Alpaca shearing 2023

Prologue

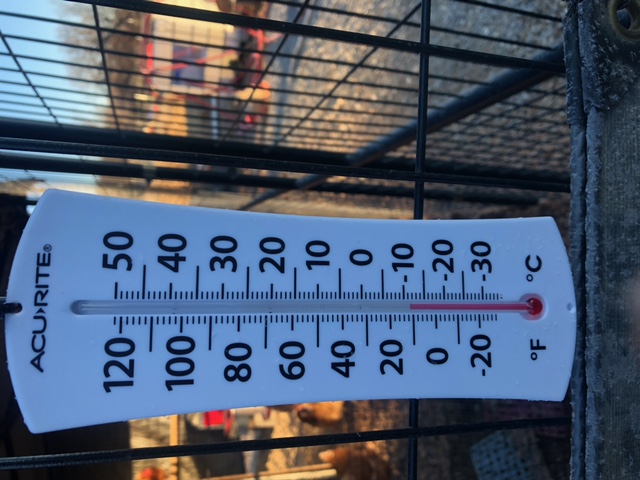

Praise God, we made it through the winter and most of the animals made it as well. We now had to shear the alpacas before the temps started raising above 60F. This is a post on our first shearing experience of our alpacas.

We also had scheduling challenge, as my bride has been traveling to Charleston SC to care for her terminally ill dad, since early October for several weeks at a time. This has put undue stress on her body and mind, as she has been only able to spend few days in between on the farm. I have been trying to manage the farm solo for six months, and since its survival mode, I havent gotten to all things I wanted to have ready for this shearing. A more detailed post on how I had to deal with the farm solo, coming in summer.

Shearing options

We raise alpacas for their fleece - wool/hair. There are two kinds we have: hyuacaya and suri. The former has springy sheep like wool while the latter has a hair like finer quality wool. Since they are camelids and big to handle, we looked at two options to shear. The first one is to get a table trap where the alpaca can be fit on to a table top and rotated around for us to shear. The other is to use ropes to stretch them out on the floor and shear them. In either of the cases, shearing happens using electric shearers, similar to your barbershop trimmers, with elaborate setup and blades to handle animal fleece.

For our purpose we went with a friend of ours from Australia who shears in the midwest in spring, using the “rope on the floor” method. He has been doing this forever and can get done with an alpaca in under 4 minutes.

Setup

Since the shearing is on the ground, we needed a concrete/flat area with anchors for our friend’s pulley system to work. We ended up building a shop/milk area for future, which we purposed for shearing. A detailed post coming on that separately.

This flat area needed to have over 21ft of run space, as there is a runner who takes the rope when the legs of the alpacas are tied and stretches them out which enables the shearer to shear unhindered. In addition we needed to have help to keep the process moving, to catch the fleece as they are shorn based on quality etc. to move them into three piles - prime keep, secondary keep and waste. The goal is to have enough space around that the fleece can be picked up without causing tears as the blanket (the full contiguous fleece of the prime keep) can be preserved.

Some folks try to do health checks and injections etc. on the same day as shearing, but we decided to reduce the stress on these animals and did our health check almost a week prior to shearing.

We also needed staging areas to bring the animals in, so they can be moved through shearing. The main thing we had to worry about was that they stayed under cover 24 hrs prior, since any moisture will spoil the fleece and sometimes render it unusable.

In our shop/building we put up had leantos to keep them under, but since we had a torrential rain storm the day prior, we packed all of them in our barn - all 14 alpacas split between machos (males) and hambres (females). We also only fed hay to ensure there was no challenge to their system.

Shearing day

The shearing day started the day prior, as my bride had to prepare for the 20+ folks we were expecting and given it was in the morning, she prepared breakfast tacos the day prior and started warming them overnight in few ovens in our sunroom (since our kitchen is not ready and the RV kitchen is unusable for anything over 2 people).

The help consisted of our two sons, our alpaca mentor couple, a friend who was local and a friend and his family visiting us from Indiana. In addition we had few neighbor friends that also were going to stop by.

We had talked through the workflow and since we had our alpaca mentors arrive first thing in the morning of shearing, I asked the man to be the foreman on the shearing floor and the lady to help my bride sort and catch wool. They are both older, but well experienced and without them, we would have been lost. We thank God for their friendship and presence that day. They missed their church activities to be with us.

One of our son was the runner and in the shearing area, while our other son worked with me in the barn to transport animals back and forth to the shearing area.

The shearing went extremely well and the alpacas did great. This was the first time for some of the younger ones and they also did well. In all, we had good confirmation of the fleece we harvested, even though, most of this herd were rescue kind and not in top shape when we picked them up. Our alpaca mentor commented that the fleece closer to the skin was markedly well crimped (technical term for assessing quality of fleece) than closer to surface, indicating our care for them and feeding change when we took over.

We were done shearing in under 90mts from when we started, which included some hiccups transporting alpacas as we didnt have enough folks to walk the alpacas and we had to sort them based on color tones while brought them over. We also took a quick break switching between males and females.

Lessons

Although all went better than expected, we will rearrange some things next time around. The first is to ensure we staged the alpacas close to shearing in order we want them sheared based on lighter color to darker. We also will have more solid help in terms of muscle power available the entire time so we can cover the animals in the 2-3 minutes timeframe, so they dont stress. We also will try to do it in early April or late March so as to have cooler weather. We can always coat them if the temperature drops post shearing.

In all, it went better than we deserved and we thank God for all.

Godspeed and onward.